Our Service

Manufacturing

A high manufacturing depth enables us to achieve highest levels of quality and short delivery periods. Subject to required quantities the following manufacturing processes are in use:

In addition to using state-of-the-art tooling machinery, our highly qualified staff represent the cornerstone for the flawless quality production of customer-specific drives. Continuous training ensures that this know-how is continually developed.

Assembly

Customer-specific gears are mounted on assembly lines with varying degrees of automation. Tables for manual work and simple devices are manufactured in-house. Robotic automation is performed together with our partner company GKW Maschinenbau in Neckartenzlingen (GKW = Gröninger / Knöll / Wolpers).

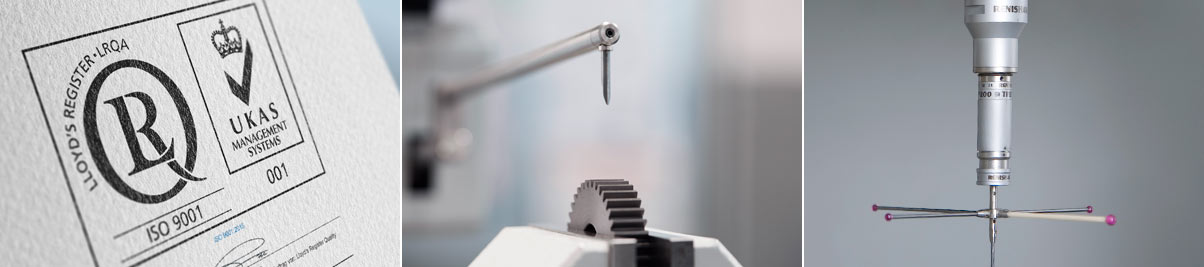

Quality

At the end of our assembly lines all drives undergo a final inspection with testing and documentation of all relevant parameters such as nominal load, power consumption and noise. In addition, our high standard of quality is guaranteed by latest QA instruments in accordance with ISO 9001:2015.

Development

From 100 pieces of milled gears to 100,000 pieces of plastic injection molding per year, you may be sure we find the best possible drive solution for your application. Why not benefit from our independency? We are not bound to individual manufacturing processes and may thus choose the most cost-effective solution for your project.

Get in contact: +49 (0) 71 27 96 06 3 - 80

We are looking forward to your inquiry.