End-Of-Life Products - We help buyers by manufacturing individual parts and assemblies when quantities are decreasing.

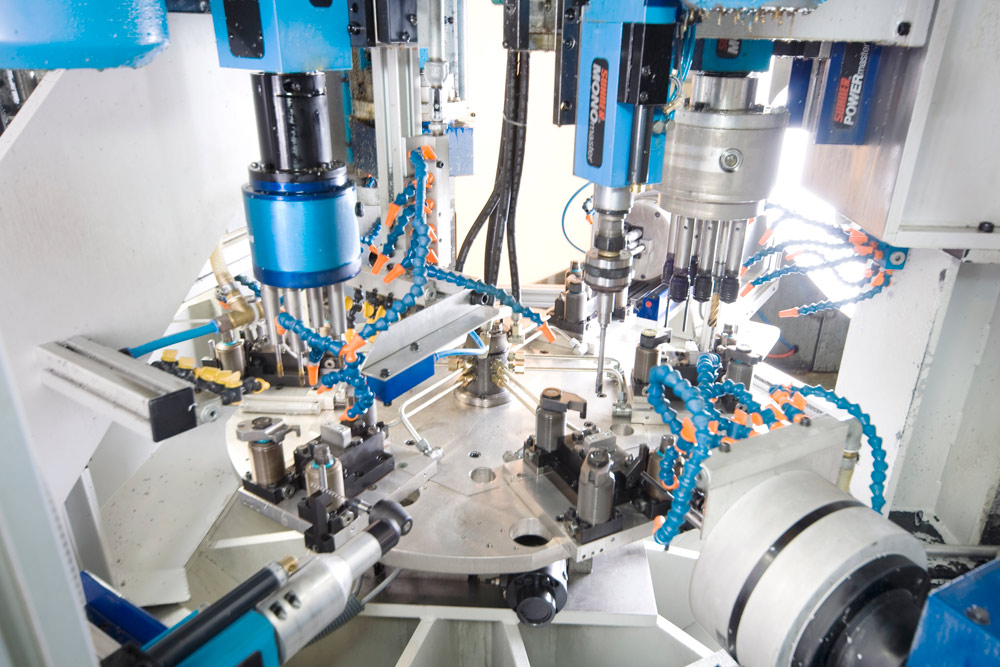

We have specialized in the manufacturing of products with decreasing quantities. Since manufacturing plants are designed for the maximum number of pieces, it makes sense to rethink the manufacturing concept in case of decreasing numbers of pieces. Often it is economical to keep parts of production lines and to manufacture single working steps for the product variants on our CNC machines. In addition to pure machining, we also offer downstream processes for your quantity scenario for end-of-life products:

Reference product: Housing for the automotive sector

Reference product: Pump housing

Reference product: Centrifugal governor

Reference product: Adjusting lever

“…because we love what we do.

Ever since the company’s foundation in 1969 we have been manufacturing with modern CNC machining centers, precisely and economically.

Robert Gröninger

Gröninger precision mechanics

In the video portrait on Youtube

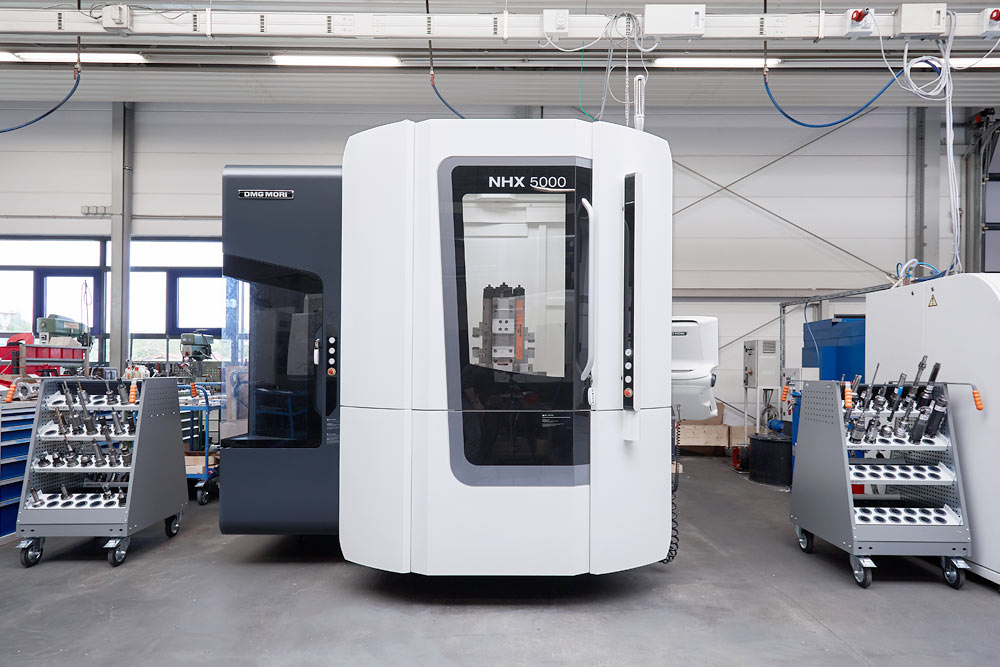

Our machines

Find out more about our machines

Quality

Our certificate from Quacert for quality management

Environment

Our certificate from Quacert for environmental management